X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

Precautions for group hoist operation

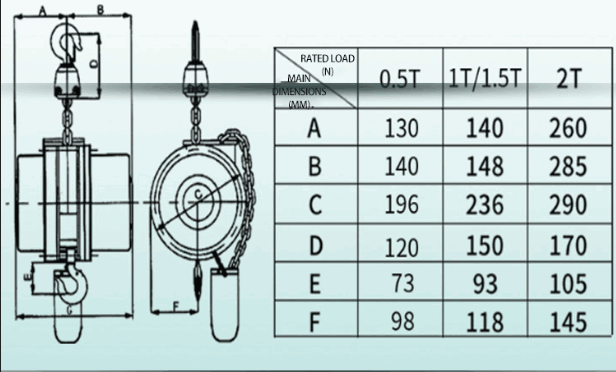

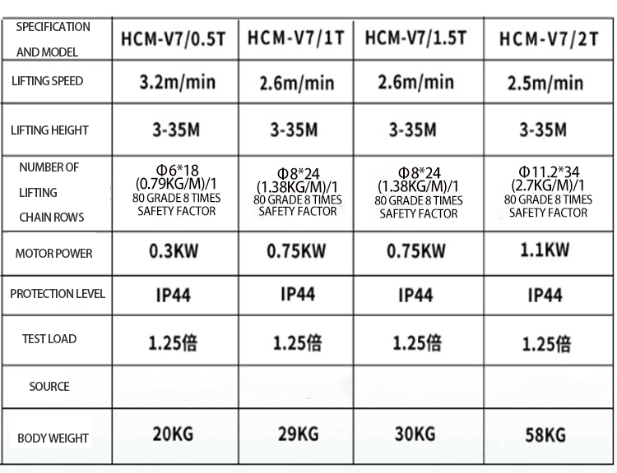

Category : V7 Stage Electric Series

Get a Quote

Product Details

Precautions for group hoist operation

1、 Pre use inspection of group hoist:

1. There should be no obstacles within the walking range of the operator and on the route through which heavy objects pass.

2. The manual buttons should move accurately and sensitively in the up, down, left, and right directions, and the motor and reducer should have no abnormal sounds.

3. The brake should be sensitive and reliable.

4. There should be no foreign objects on the running track of the group crane electric hoist.

5. The action of the upper and lower limit switches should be accurate.

6. The locking nut of the hook should be tightened.

7. The hook should rotate flexibly in both horizontal and vertical directions.

8. The hook pulley should rotate flexibly.

2、 During the use of the group crane electric hoist, if any faults are found, the main power supply should be cut off in a timely manner.

3、 The lubrication parts of the group crane electric hoist should be promptly lubricated with an appropriate amount of lubricating oil, which should be clean and free of other impurities. Lubricating oil should be replaced approximately every 2 months. Sufficient lubricating oil must be added to the lifting reducer and operating reducer before use.

4、 When the group crane electric hoist is not working, it is not allowed to hang heavy objects in the air to prevent deformation of components.

5、 After use, it should be parked in a safe place. Rainproof covers should be installed outdoors.

6、 The electric hoist for group hoisting shall not be used to lift or unload heavy objects on the side, and overloading is prohibited.

7、 After completing the work, turn off the main power switch and cut off the main power supply.

RELATED PRODUCTS .

Stage lighting-specific lifting slings are hoisting accessories specially developed for stage lighting fixtures such as PAR lights, moving head lights and profile lights. Their load capacities are cus

The lightweight stage electric winch is an electric hoisting winch specially R&D and designed for stage hoisting operations. Featuring lightweight and compact core structural characteristics, it i...

Space-constrained scenarios are the core pain point when building stages in indoor venues such as small theaters, banqueting halls and multi-functional halls. These venues generally suffer from narrow

The power-free manual chain hoist is a manual hoisting device that requires no external power drive and relies on human force to pull the chain to lift, lower and move heavy objects horizontally. Adop

2025-11-05

创始人

0

GET show Guangzhou International Performing Arts E...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2025-11-05

创始人

0

Guangzhou International Performing Arts Equipment ...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-05-27

创始人

0

Guangzhou International Professional Lighting and ...

We look forward to meeting you at the exhibition site and jointly drawing a new blueprint for industry development!

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...