X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

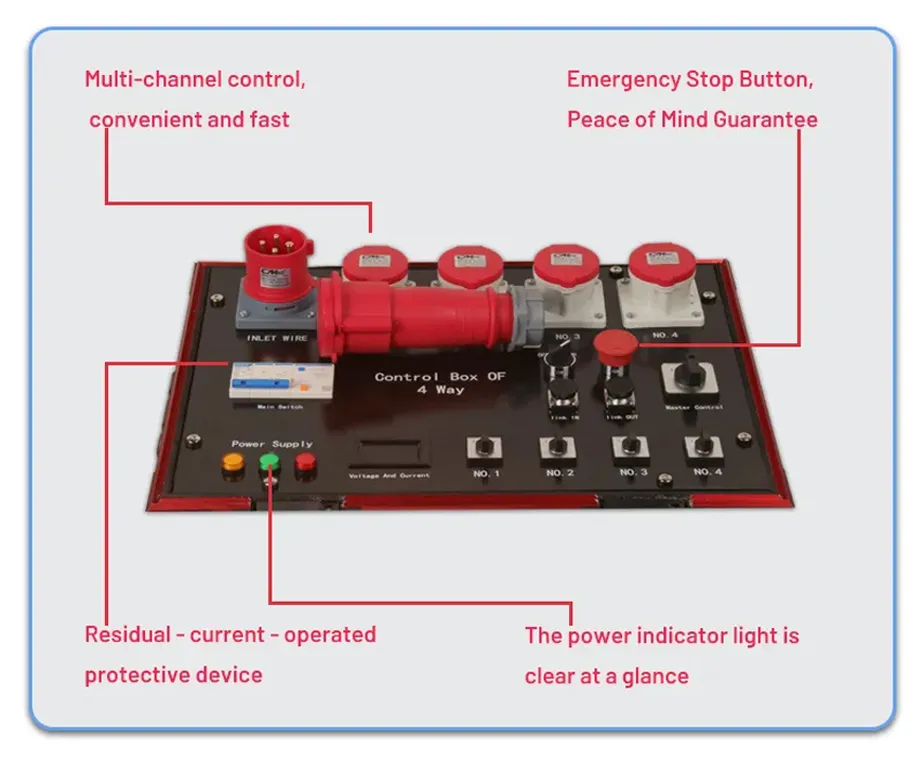

The advanced lighting hoist controller is a high-precision and intelligent control device specially designed for lighting hoist systems. This controller usually also incorporates status monitoring and

Category : Controller

Get a Quote

Product Details

To ensure that the dual braking system of the advanced lighting hoist controller remains reliable at all times, operators must carry out a monthly refined testing process. First, in the no-load state, trigger the emergency stop command through the advanced lighting hoist controller, and observe the response time of the electromagnetic brake (the standard value is ≤ 0.5 seconds) and whether the brake wheel is completely locked. Then, manually release part of the rope tension to test the triggering sensitivity of the mechanical pawl, ensuring that the pawl can accurately engage with the ratchet without jamming. In the full-load testing phase, it is necessary to load 1.2 times the rated load of the equipment (for example, a device with a rated load of 20kg should be loaded with 24kg) to simulate the braking effect under the most severe working conditions. Start the equipment, raise it to a height of 1.5 meters, then trigger the emergency brake, and use a laser rangefinder to measure the braking sliding distance. Under normal circumstances, this distance should be strictly controlled within 5cm, and the dual braking system must take effect simultaneously (the electromagnetic brake first cuts off the power, and the mechanical pawl synchronously locks to prevent secondary sliding). If during the test, there is brake delay, excessive sliding distance, or failure of any braking system, the equipment must be stopped immediately. Contact professional technicians for maintenance, replace worn brake pads, pawls, or adjust the spring tension until all indicators meet the safety standards before putting it back into operation.

Previous: Performance Electric Hoist Controller

RELATED PRODUCTS .

The safety truss hoist is a safety-type electric hoist specially designed for the hoisting scenarios of stage trusses. It is suitable for the suspension, lifting and fixing operations of various stage

Stage lighting-specific lifting slings are hoisting accessories specially developed for stage lighting fixtures such as PAR lights, moving head lights and profile lights. Their load capacities are cus

The lightweight stage electric winch is an electric hoisting winch specially R&D and designed for stage hoisting operations. Featuring lightweight and compact core structural characteristics, it i...

Space-constrained scenarios are the core pain point when building stages in indoor venues such as small theaters, banqueting halls and multi-functional halls. These venues generally suffer from narrow

2025-11-05

创始人

0

GET show Guangzhou International Performing Arts E...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2025-11-05

创始人

0

Guangzhou International Performing Arts Equipment ...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-05-27

创始人

0

Guangzhou International Professional Lighting and ...

We look forward to meeting you at the exhibition site and jointly drawing a new blueprint for industry development!

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...