X

Electric hoists represent their own machinery, strength, and toughness, while the stage is elegant, flowing, and soft, with conflicts and collisions between the two.

The stage specific electric hoist belongs to the chain type electric hoist. The stage electric hoist is strictly designed and manufactured in accordance with the requirements of touring performances a

Category : W12 Stage Electric Hoist

Get a Quote

Product Details

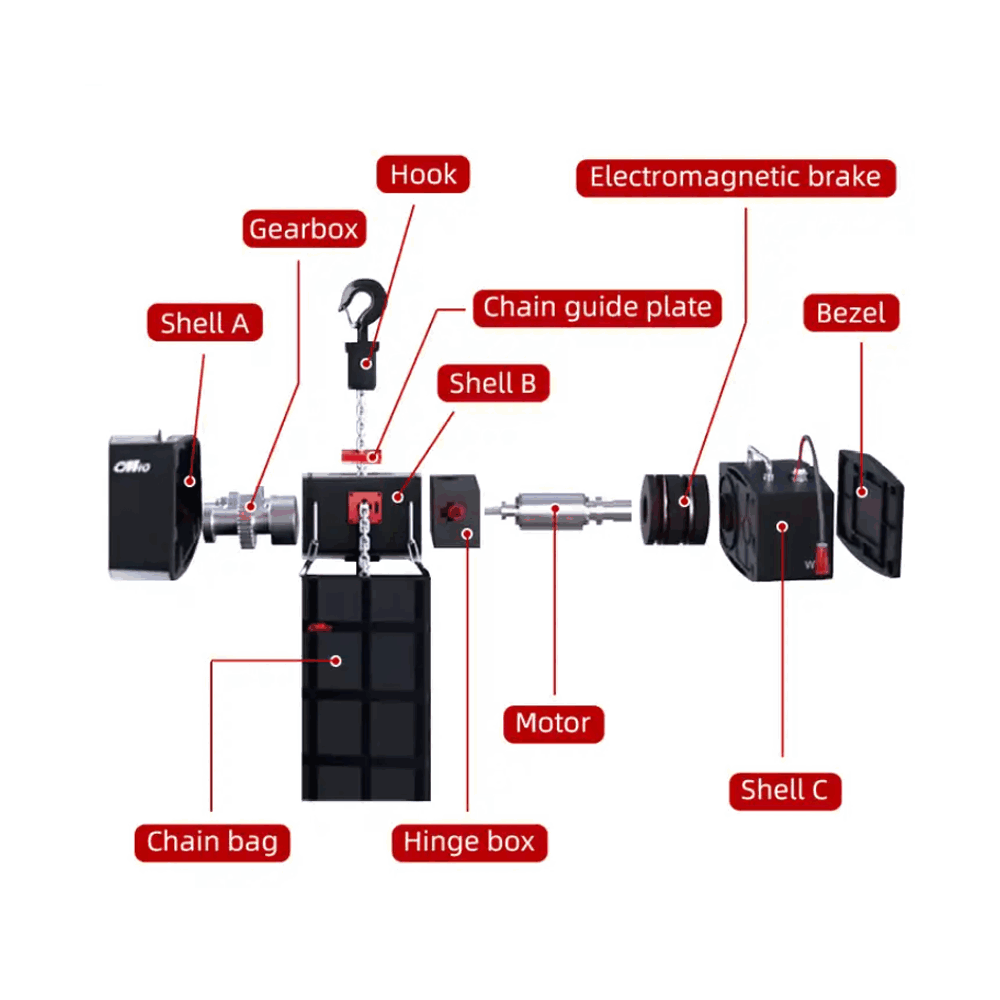

The stage specific electric hoist belongs to the chain type electric hoist. The stage electric hoist is strictly designed and manufactured in accordance with the requirements of touring performances and exhibitions, with a black paint treatment on the surface, long-lasting brightness, and a 380V control circuit heat treatment. The formed steel guide chain plate is designed for both forward and reverse directions and all-weather use. It is equipped with an adjustable spiral limit switch, which has higher reliability performance. The chain is galvanized and not easy to rust. Lubricating grease is installed in the gearbox to prevent oil droplets from penetrating the stage. The motor of the hoist is sealed in an aluminum steel ring cylindrical shell, and the motor is permanently connected to various controllers and circuit distributors.

Features of stage electric hoist:

1. Lightweight, beautiful, and durable plastic chain bags.

2. Stamped steel shell, lightweight and sturdy.

3. High strength safety hook, capable of withstanding unexpected overload impacts without breaking, and will only gradually deform when overweight.

4. Efficient, lightweight motor, asbestos free brake system, low energy consumption.

5. Limit switch: There is a limit switch device on both the upper and lower parts of the crane to automatically stop the motor, prevent the chain from exceeding, and ensure safety.

6. Steel guide chain plates formed by heat treatment.

7. Easy to operate and maintain.

8. Designed for both forward and reverse directions and all-weather use.

9. Equipped with adjustable spiral limit switches for higher reliability and performance.

10. Suitable for connecting to various controllers and circuit distributors.

11. Lubricating grease is installed in the gearbox to prevent oil droplets from penetrating the stage.

12. The motor of the gourd is sealed inside an aluminum steel ring cylindrical shell, permanently protecting the motor.

13. The chain is galvanized to prevent rusting.

RELATED PRODUCTS .

The electric hoist for stage audio equipment is a professional hoisting device made of high-strength lightweight alloy with an integrated compact structure. Its rated load capacity is precisely matche

The stage show hoist controller is a core control device that integrates safety protection command transmission functions such as limit protection and overload protection, used to accurately control t

The truss-specialized electric winch is a hoisting device equipped with precise limit and overload protection, specially designed for the lifting and shifting operations of stage trusses.

The control of lifting speed of high-quality manual chain hoists is directly related to the type of load borne by the chain, and is an important factor affecting the service life of the chain. During

2025-11-05

创始人

0

GET show Guangzhou International Performing Arts E...

Tianjin Kemei Machinery Manufacturing Co., Ltd. has been deeply engaged in the stage equipment manufacturing field for many years and has developed into a modern benchmark e...

2025-11-05

创始人

0

Guangzhou International Performing Arts Equipment ...

In the era of the rapid development of stage lifting equipment and intelligent acousto - optic technology, every industry event serves as a crucial opportunity for innovatio...

2025-05-27

创始人

0

Guangzhou International Professional Lighting and ...

We look forward to meeting you at the exhibition site and jointly drawing a new blueprint for industry development!

2025-02-28

创始人

0

The participation of Tianjin Kemei in the Guangzho...

Tianjin Kemei made a remarkable and eye-catching appearance at the Guangzhou (International) Performing Arts Equipment, Intelligent Acoustic, Optical and Electrical Products...